Simplicity and simplification is one of my favorite topics. When it comes to product lifecycle management (PLM), product data management, supply chain management, and product development process, the topic of simplification always turns out to be a very interesting thing. This is where we can hear a lot of customer feedback about how a PLM system failed or succeeded. This is where a lot of debates about how to implement a specific methodology in the product lifecycle come into play. The discipline of product lifecycle management is very much divided between to call it technology, product, methodology, and business strategy. The product lifecycle is complex and process management for any industrial company cannot be easily described in a few minutes. Companies that design and build products are complex and their product’s lifecycle can be different. Although all of them can be called “industrial companies”, PLM solutions to satisfy their needs, to ensure document management, computer-aided design, PLM technology, and PLM system can be very different.

Many years ago, when I came to the enterprise and engineering software industry I was told – enterprise software is a business, no one is buying it for fun, so it is ok to be complex. These enterprises are complex and software for them is complex. Complexity requires services and education, so it is a win-win. We can give them software and teach them how to use it, they pay us and everyone is happy.

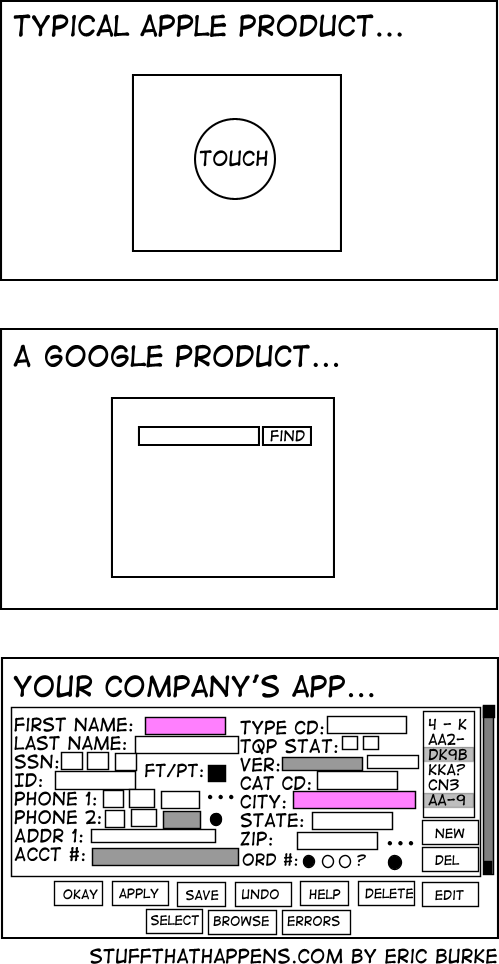

My aha moment goes back many years when I was talking to one of the customers about the product we made (I was developing applications data management applications for AutoCAD back in those days). The customer looked over all buttons, menus, and settings we demonstrated to him and said – “I want a single-button application”. Please call it “do what I need”. While I understood it was a joke, it eventually lead me to this picture.

Simplification Trend

The demand for simplification is high. And there are good reasons why simplification is very powerful. Simplification saves time, makes things understandable, includes more people, improves experiences, enhances problem-solving and innovation, and reduces stress. It’s a powerful trend that helps us navigate our complex world more easily. Think about the following things and how simplification can help.

- Understand quickly: When things are complex, simplification breaks them down into easy-to-understand parts. This saves time and helps us make informed decisions.

- Save time: Simplification removes unnecessary steps or complications, making tasks and processes faster and more efficient.

- Include more people: By simplifying information, we make it accessible to a wider audience, including those with different backgrounds or abilities.

- Improve experiences: Simple designs and intuitive interfaces make using things easier and more enjoyable, leading to happier users.

- Solve problems and innovate: Simplification helps us identify key issues and develop effective solutions. It encourages creative thinking and opens doors for new opportunities.

- Reduce stress: Complexity can be overwhelming. Simplification brings clarity and order, reducing mental strain and improving well-being.

There are no debates about simplification in general. But the devil is in details and this is how we can to the main question – Can PLM be SImple?

Can PLM Be Simple?

I wrote many articles about PLM and simplicity. I talked to many people and discussed it with engineers and industrial companies. In a business, it is always good to ask Who needs Simple PLM? I also learned Hard Things About Simple PLM. These articles are old, but still relevant in my view. The following picture from Jos Voskuil’s article is still very relevant:

Jos Voskuil’s article (again) touched the nerve of “simplicity” in his recent Modern PLM Is Too Complex article. Here is the passage from the article (actually a quote from Frédéric Zeller)

I am stunned by the average level of posts on the PLM on LinkedIn. I’m sorry, but in 2023 :

- Part Number management (significant, non-significant) should no longer be a problem.

- Revision management should no longer be a question.

- Configuration management theory should no longer be a question.

- Notions of EBOMs, and MBOMs … should no longer be a question.

So why are there still problems with these topics?

The concluding remark by Frederic is important to understand:

There is a refusal, which turns into a denial, of complexity among users and customer PLM managers. If you mix (and you have to mix !) digital thread between the different product views (EBOM, MBOM, SBOM …), change management – implying revision management and traceability -, you quickly get something that seems very complex, even looking unmanageable by end users.

Sorry, guys, but even if the functions are well implemented in a PLM solution, configuration management (taken in its broadest sense) is, and will remain a complex topic. Insuring traceability between engineering and manufacturing views of a product is a complex task. To manage it, the PLM solution must be efficient, the PLM implementation must be rigorous, and users must be trained.

I agree with every word of this conclusion. Building products and services is complex and although everyone will tell you that BOM is a simple list of parts in Excel when it comes down to managing them across multiple products, different contractors and suppliers, and changes, things will become complex really, really hard. So, what to do?

Virtuous Simplification – Simple, But Not Simpler

“Everything should be made as simple as possible, but not simpler”. This quote, usually attributed to Einstein, is often used as an appeal to make a subject as simple and easy as possible to appear in front of customers, though of course don’t make it so easy that it becomes pointless and meaningless.

Going back to my example of a “single button application”, I can see how pathetic can be an attempt to bring EBOM to MBOM transformation or change impact analysis that requires multiple people coordination and collaboration. At the same time, I can see how CAD add-in should be capable to capture the data from the CAD system without engineers doing thousands of mapping settings.

And this is where the art of virtuous simplification comes into play. It is important not to turn into vicious simplification, which is a brute reductionism to ignore complexity and bring ambiguity. This is the picture of “complex but hard” vs “simple, but wrong”. When it comes to knowledge and learning, it is always important how not to delude knowledge by ignoring and obfuscating the complexity of organization and processes (Frederick’s point).

How make it applied in the context of an unstoppable PLM playbook and make things simple?

PLM Implementation and Industry Context

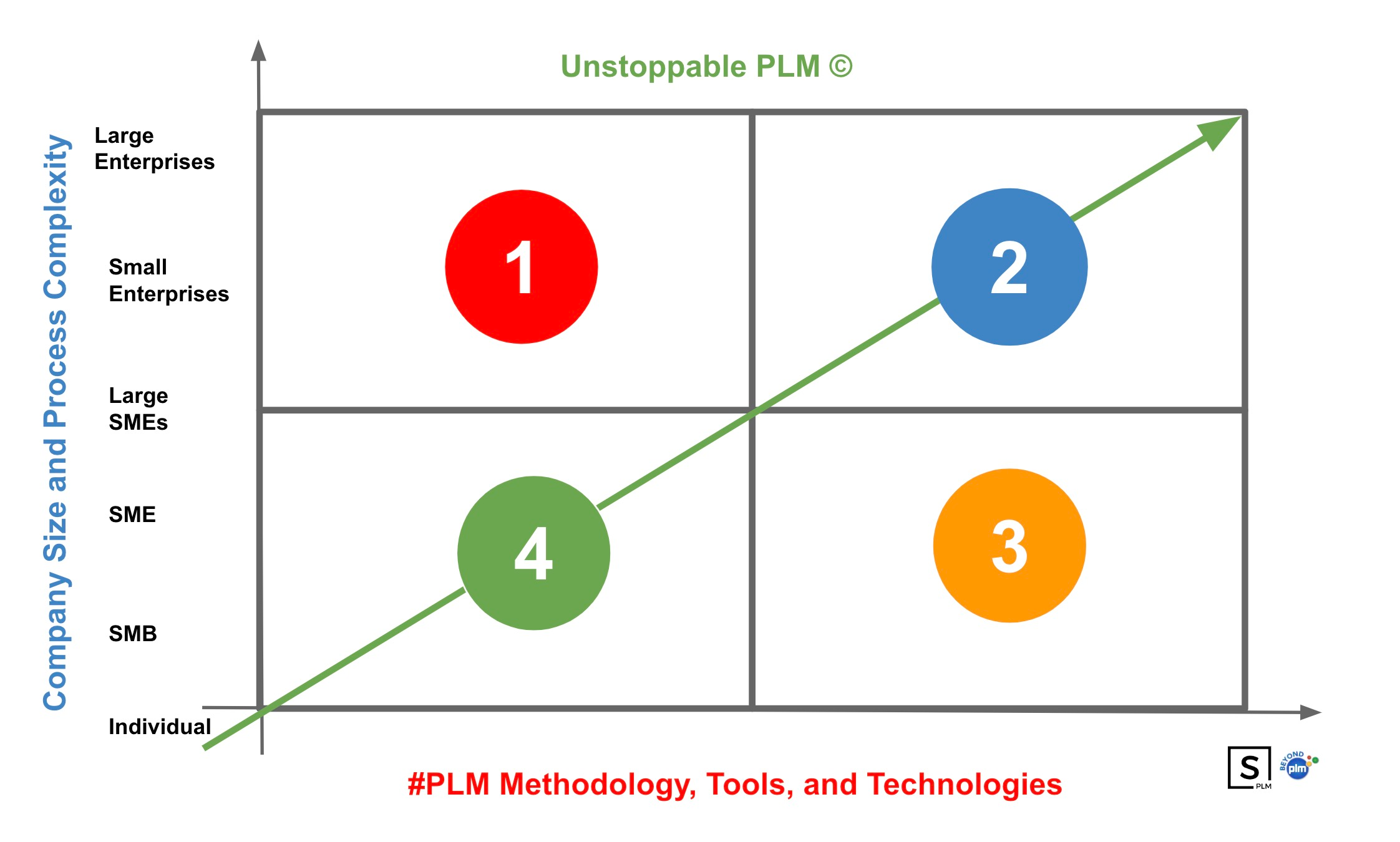

How to bring the right tool and right methodology to PLM implementation? This is where things go wrong very fast and I’ve seen it in many implementations. To make the implementation successful, you need to bring the tool that can help you to identify the right PLM solution. This is how you can make your PLM implementation unstoppable. Check the picture below I like to use to explain how to do so:

As you can see the organization size really matters when it comes to PLM implementation (actually, it is true for any IT project). There are so many PLM tools and technologies. They might or might not fit the organization you’re trying to implement PLM. Here are some examples of the segments:

- Horizontal scalable tools

- Broad “industry” level complex implementation

- “Scaled down” enterprise tools and OOTB approaches

- Simple tools developed for individual and small customers

What makes it powerful is that the middle green line usually identifies the right balance between products, technologies, and organization size. But things are not simple. I’ve seen how “1” was successful. The “2” is how many enterprise PLM implementations are done these days. Sometimes, “3” can be successful too, but the context is really important. Usually, a “4” is a good tool, but it might be limited to scale. In my discussions with manufacturing companies and startup businesses, I always touch on the importance of tool classification and industrial companies’ segmentations. In my future articles, I will bring more specific examples.

What is my conclusion?

Simplicity is hard. The most important thing in simplification is to choose the balance of tools, methods, and company context. This is why some organizations can fail one technology and another one can make it really successful. This is also a reason for each organization to make an assessment of their processes and requirements to find the right balance of tools and methodology. Once a company can achieve that, we will see much fewer questions in the industry about Part Number debates, configuration management, lifecycle and revision management schemas, and many other questions that trigger multiple debates on LinkedIn. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital thread platform including PDM/PLM and ERP capabilities that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

The post How To Make PLM Simple, But Not Simpler appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.