Integration was a big deal for manufacturing companies implementing PLM systems for a very long time. It is very rare to see how the entire product lifecycle management process can fit a single software stack. Manufacturing companies were always divided between hedging their risks with multiple vendors and looking at best-of-breed approaches on one side and placing all eggs in a single basket of one CAD/PLM vendor with a fully integrated platform.

I found the best way it was presented by Marc Halpern of Gartner. A single vendor black hole is a serious thing. As manufacturing is moving forward with digital transformation goals, the question about integration vs usage of a single vendor platform will be coming again and again.

What makes product lifecycle management and product data management really complex these days is the complexity of business processes, distributed product value chain, and increased risks of supply chain management. Global manufacturers are operating in a distributed way, companies are located everyone and need to operate in an agile and flexible way to adapt to changing realities of the operational environment.

At the same time, companies are looking more and more into how to get up-to-date information and real-time data analysis done across multiple applications to satisfy the needs of many organizations working together. The question about data sharing and exchanging data during a product’s lifecycle is a real thing, The time when computer-aided design (CAD) systems were saving data in the LAN folder (or local PDM system) is long time gone. Companies are looking for greater visibility and connectivity.

Cloud Technology and Integration Landscape

Modern cloud technological advancements are changing the way data can be managed and how systems can be integrated. Integration technologies made a long way from simple object access protocol (SOAP protocol) and standardized XML messaging system to exchange data to the universal description of services, web services use, discovering web services and many other elements of programming language, REST APIs and iPaaS (Integration Platform as a Service) helping to simplify and improve the way integration can be made.

Think about what’s new in PLM integrations and what is the future of data services and REST APIs in transforming the integration process. I highly recommend you my earlier article from this year – A post monolithic PLM world – data and system architecture. These are 5 fundamental level elements of the new PLM system architecture of the 2020s that I’m sure are in the development and adoption by many manufacturing companies and PLM vendors:

- Polyglot data architecture

- Multi-tenant data models

- Semantic modeling layer

- Digital thread support

- Connected user experience.

Web services play a key role in making this architecture create new ways of integration, which open the door to adopting a multi-cloud PLM strategy.

Multi clouds Are Coming. Are PLM vendors ready?

I will say something that can disappoint PLM vendors in general. It is related to one of the most “sweet” sweet words in PLM marketing language – a platform. Nothing wrong with that, platforms are still important. However, industrial companies don’t look at PLM as a platform. For these manufacturing companies, AWS, Azure, and GCP are platforms that they see as a vehicle for digital transformation. And these platforms are notoriously competitive when it comes to the usage of these infrastructures. Just as one example, check the article about Pentagon’s decision to go multicloud – Pentagon Goes Multicloud! Amazon, Google, Microsoft, Oracle to Collaborate on $9B JWCC Deal.

PLM vendors are catching up really fast by introducing their PLM system hosted using one of these platforms. While setting compatibility with AWS, Azure, and GCP can help vendors to make a first ‘pass’, the next one can be even more interesting.

A typical legacy PLM system hosted on AWS is not very different from on-prem solutions. Data management (mostly single tenant) and integration capabilities of these systems is not very different from what was developed back in the 2000s. Check my earlier article – How to compare SaaS PLM systems?

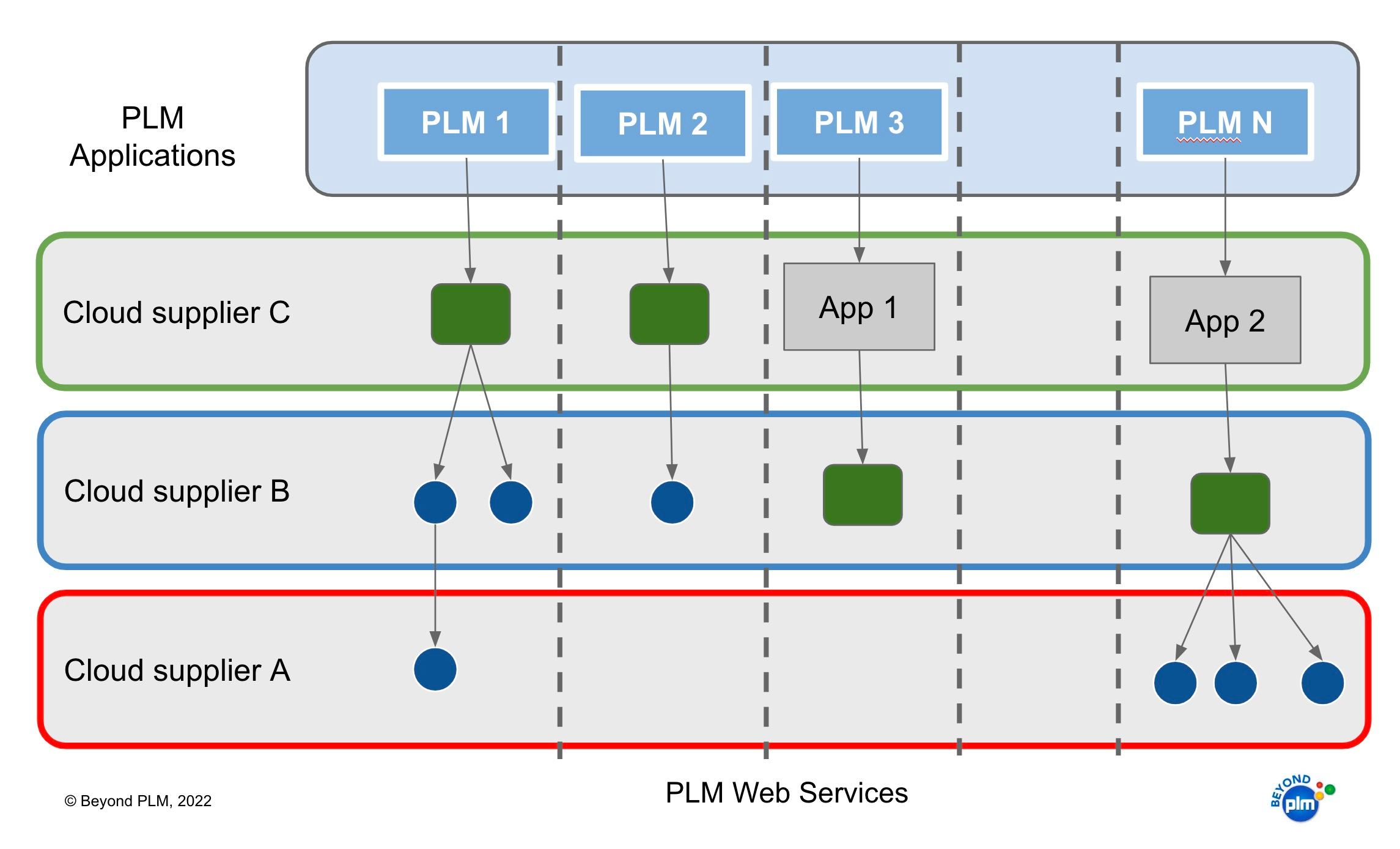

Now is the time for IT departments of industrial companies to catch up and learn beyond the “we can host it on AWS” playbook. Because in the next few years, the world of PLM implementations will look like this one- multicloud and web services will rule the process and enable integrations.

Introducing multcloud PLM architecture with web services will bring a new level of technology and operating system for PLM helping manufacturing companies to organize web service testing, web-based applications, client application transformation, in general, application development for the PLM domain.

What is my conclusion?

New cloud PLM architectures are coming. They will be different from what was known as “PLM platforms” in the next 15-20 years. The goal will be to open up and go beyond a “single vendor blackhole” towards integrated multi-cloud PLM systems relying on integrated PLM web services. AWS, Azure, and GCP will become a vehicle to introduce these web services to enterprise companies. What PLM services will be available there will define how successful PLM vendors will be in this future integration game. It is the time for the IT of industrial companies to upgrade their technology and architecture skills. It is time to go beyond the “we can host it on AWS” mantra toward new PLM architectures. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital cloud-native PDM & PLM platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

The post Integrated PLM Platforms and Multi-Cloud Web Services appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.