The manufacturing industry is going through the process of digital transformation. The central part of digital transformation in every industry is changing the way companies are treating the data. The data must become a first-class citizen. A digital BOM (Bill of Materials) is the next step in streamlined engineering and manufacturing. By digitizing your BOM, you can improve communication between departments, automate processes, and save time and money. Historically engineering and manufacturing formed the two biggest silos in manufacturing companies. Therefore, the question is about how to streamline their processes and improve efficiencies. While I doubt some companies are still using paper-based communication and processes. On the other side, many existing processes are linked to very outdated best practices of handling product information using separate systems, Excel spreadsheets, Bill of Materials printed on the face of 2D Drawings. In this blog post, I will discuss touch both EBOM and MBOM best practices and the trends I can see in moving from siloed and outdated data management practices to the connected digital environment. I will also talk about how companies can make a switch from their current methods of work to adopt modern methods and services.

EBOM vs MBOM Divide

For many years of business practices, companies found a huge divide between MBOM and EBOM both conceptually and technologically. For most companies, ERP /MRP systems were leading the way of building manufacturing planning solutions and advocated for a solution where MBOM as a master data to control everything that goes to the product. As product complexity grows, especially for advanced and configured products (eg. aerospace, automotive, defense) PLM systems were introduced to manage product information and introduced EBOM solutions to manage data about products, such as design, variants, configurations, and others. Such architecture, as well as, PLM-ERP integrations for many years remained one of the most complex topics. I wrote multiple articles addressing this problem. Here are some of them.

Why do the future PLM-ERP integrations go beyond moving data from point A to point B?

PLM and ERP- how to achieve synergy?

PLM+ ERP integration and future digital thread

Companies are heavily struggling around product information management and BOM in particular. As we move towards digital business, the question about modern data management and BOM organization is one that I can see on the top of companies’ minds. Old siloed paradigms won’t live and companies that think about “good old days of throwing CAD BOM to manufacturing to build stuff” won’t survive.

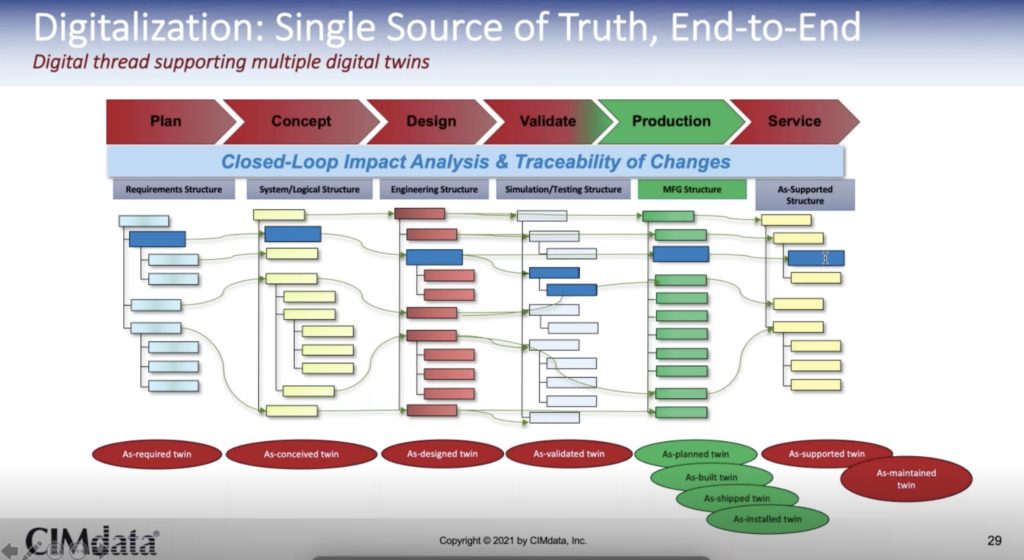

From BOMs To Digital Twins And Threads

My attention was caught by the CIMdata webinar – Why an mBOM Alone Isn’t Sufficient? In this webinar, John MacKrell, CIMdata chairman and long-time practitioner and advisor in PLM and related disciplines, discusses why an MBOM may serve some of the use cases, but fell short to provide a reliable business practice for modern manufacturing companies, especially since the complexity of products and processes is growing. I recommend you to check this out. The webinar sends a strong message about the limitations of siloed approach and reliance on old fashion MBOM data architecture. The following two slides I captured can give you an idea. There is a bit of a “renaming” game there. You can see a “Twin” name shows in many places where many of you are regular to see a “Bill of Materials” – As-designed, As-planned, As-built, etc. I’d not recommend seeing it as a simple renaming. The data companies need to manage is much more complex and relationships between data need to be managed.

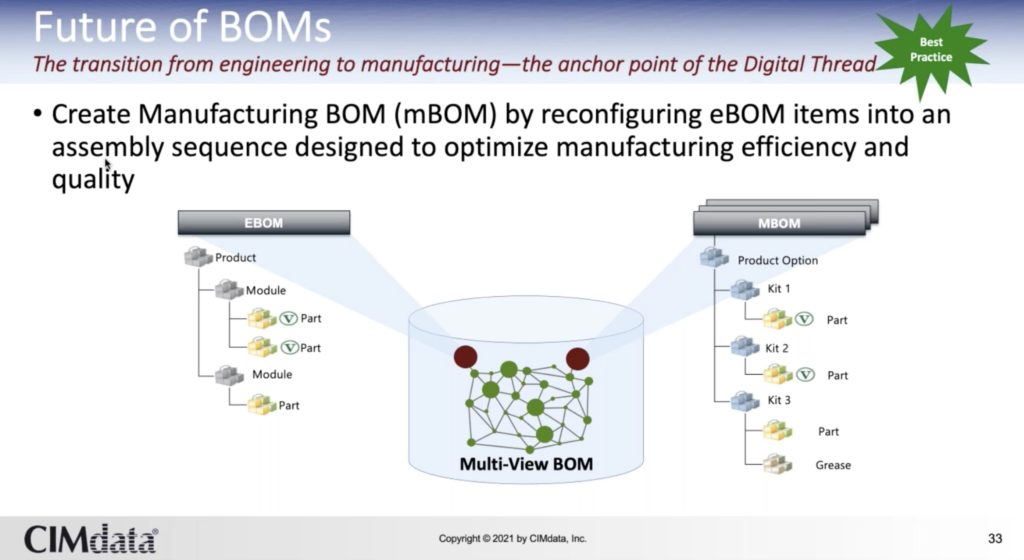

The second slide speaks about the future – multi-view BOM. According to CIMdata presents, this is the future architecture of BOM and Digital Thread allowing to a connection of multiple pieces of information and managing the so-called Digital Web (I will talk about it in my future articles).

Why Do Companies Need To Make A Change?

Every time, software vendors, analysts, and technology visionaries are suggesting to manufacturing companies to make a change (or adopt new tech), the obvious question of “why” comes up. If it works, don’t change it- a favorite statement you can hear in many manufacturing companies.

Product Complexity

Although you can find some exceptions, most modern products are a combination of mechanical, electronics, software, and sometimes, business services delivered via cloud services. You don’t need to go far away to bring examples. A simple smart home doorbell has all these pieces. The complexity of managing these products and related services are skyrocketing in all disciplines – engineering, manufacturing, maintenance, and support. Think about the need to figure out what camera, electronics, and software are installed in a specific version of the doorbell for a specific customer. Now think about the need to explore multiple systems and Excel reports. You don’t want to be a person who needs to do so.

Manufacturing and Supply Chain Complexity

Production is another level of complexity. Unless you live under a rock for the last couple of years, you’ve heard about supply chain shortages and production complexity. Companies are manufacturing under super complex requirements and manufacturing realities. Building products for multiple regions, regulation requirements, and managing the complexity of the supply chain brins the need to have a robust data architecture to get the right information at the right time in front of the right people. Making changes in such an environment is the next level of sophistication that can be achieved alone with an MBOM stored in an MRP/ERP system.

Business Moving from Products to Services

Last, but not least is business. Companies are expanding and transforming their businesses from selling products that can be shipped from the production docking lot to services that need to be monitored, updated, fabricated, and utilized. It brings another level of complexity in data management and connection between engineering bill of materials, manufacturing bill of materials, and all other data elements describing the system and their relationships.

Digital Industry Transformation

There are many benefits to having a digital BOM. Perhaps the most obvious benefit is that it allows companies to better manage their products and operations. This is an obvious requirement, but it is very hard to do. To start with companies needs to realize how to move from siloed documents used by companies for computer-aided design, electronic design automation, and separate raw materials to the information about the complete and shippable product which contains detailed engineering information, packaging materials, production schedules, shared with the manufacturing team and engineering department. The updated information must be used in the assembly process and also must connect the information about the physical product. It must connect the product development process, all the parts with accurate BOM, and the finished product together.

Conclusion

The purpose of converting an E-BOM, M-BOM, and all related information about product design, engineering, and manufacturing process to a digital BOM is to make all product information available in one virtual digital place so that it can be used for production planning and execution, purchasing, inventory management, sales and marketing, and other activities. In the next few years, companies will be less interested what is the three-letter acronym of the system that managed the data (PLM, ERP, CRM, etc.) and more focusing on how to manage information flow. In my following articles, I will continue the discussion about what are modern technologies and components of future digital BOM solutions. The manufacturers are under big stress to organize their business and to move to a single source of information access. It is the main purpose of digital transformation in manufacturing. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital network-based platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

The post From Engineering BOM and Manufacturing BOM to Digital BOM appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.