Change is the only constant thing in product development. Therefore, one of the most popular questions everyone wants to answer when it comes to PDM/PLM tools is how to go from revision A to revision B? From my experience, it is also the biggest challenge when it comes to PLM implementations.

What is PLM Revision Control

The advantages of revision control are obvious. The revision control systems were used by many industries and also by engineers and manufacturing companies. However, the way these systems work was different. The system tracks product changes, manages the release of new products and updates to existing ones, and keeps track of all versions of a product. Usage of revisions reduces errors in production by ensuring that everything stays uniform according to company standards. New features are documented so they can be accessed quickly when needed by other team members without having to search through lengthy documentation or build up experience with different systems. There are many benefits for using Revision Control mechanisms in including better communication between team members, easier access to information for employees who may not have had previous work experience with the company, increased transparency within the organization because everyone has access to relevant data at one time which eliminates discrepancies.

How does it work and main challenges

Conceptually, revision and version control is not complex function, but implementation can be tricky. It allows managing the history of changes in the way of preserving revisions and allowing to access each revision (or version) separately, including metadata and files (depends on the system). While these functions are simple, the way these technologies can apply can be very complex and dependent on many factors. Just to name a few – product complexity, file dependencies, multiple team/people involvements. All these factors can impact the way revision control can be implemented.

However, one of the biggest challenges is how to organize the process in an easy way. The process of creating a new revision is usually very tedious and involves multiple steps (especially when files are involved) – it was a pain for PDM systems for many years.

Modern Collaboration and Product Development Process

The demand to collaborate is high these days. Remote work we’ve been pushed for the last two years because of COVID just made it harder. There are technological answers. Modern systems bring new ways to collaborate. It includes real-time simultaneous editing capabilities that were first introduced in online document editing (eg. Google Docs) and later spread out to multiple products. Users like the modern collaboration methods and you can see them in many products these days. Here are a few examples you can check – Onshape (supports simultaneous geometric modeling and changes in 3D Mechanical design), OpenBOM (supports simultaneous collaboration and editing to manage Bill of Materials, item catalogs, orders, etc.)

How Collaboration will impact Revision control?

Here is an interesting question to ask. How modern collaborative systems will impact the revision control methods? On one hand, revision control is straightforward going from RevA to RevB. Why collaboration must be involved. You can find an interesting “aha moment” by digging a bit deeper. Most traditional rev control systems support the command to create a RevB from RevA, which is considered a simple operation. When you’ve got multiple people involved it is not that simple. Also, creating Revision introduces a question of allowing multiple people to make a change for this revision before the information will become immutable.

A few examples of collaboration and revision control

Over the course of the last decade, I observed how collaborative work impacted configuration management and revision control. It came from multiple systems and product development environments. I’d like to bring 3 examples coming from software, CAD, and BOM management systems.

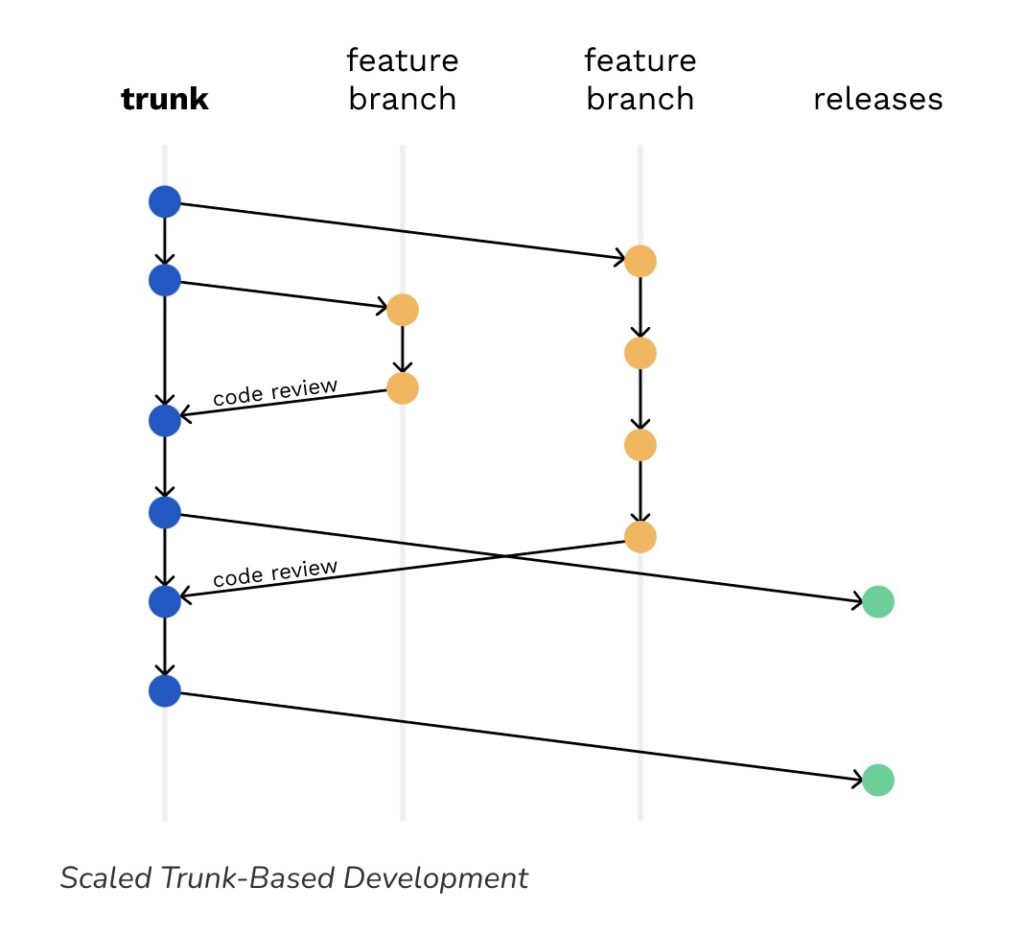

My first example is Git/Github. My hunch everyone is familiar with the system and is used by millions of software engineers. I recommend you to learn about multiple workflow processes used in GitHub. Check this article – GitHub Flow, Trunk Based Development, and Code Review. The idea of trunk-based development that gained a lot of popularity is allowing to work on separate features, but keeps a central “main” (a trunk space). The diagram below gives you an idea of how it works.

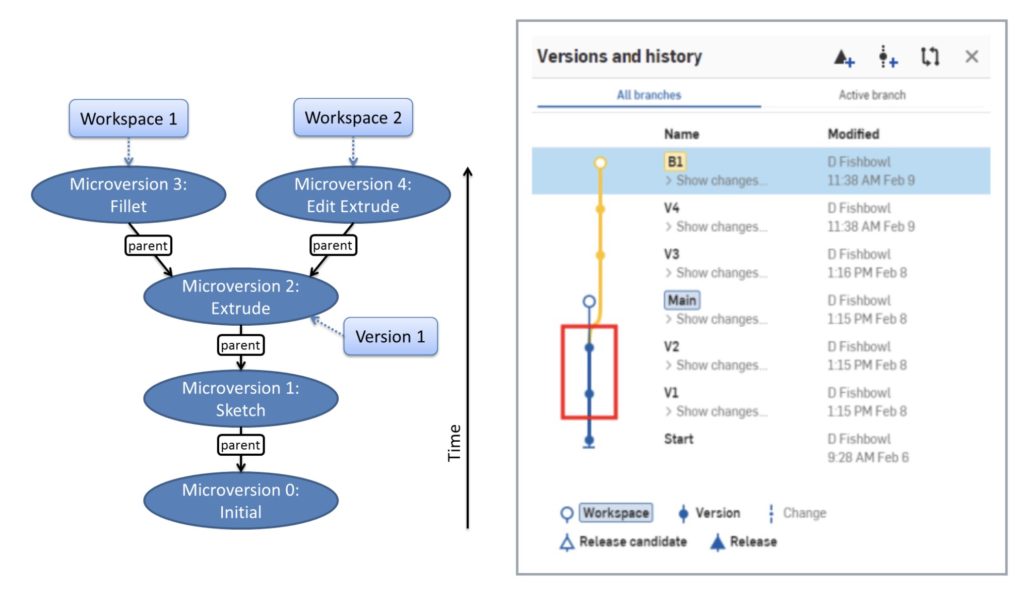

My second example is from Onshape – an online MCAD system, which can very much remind you of Google Docs. However, it is a professional MCAD system with an amazing set of collaboration capabilities and innovative version control. Check my earlier articles – How Onshape solves CAD collaboration and manages versions to get more details. The picture below gives you an idea of how Onshape version management works.

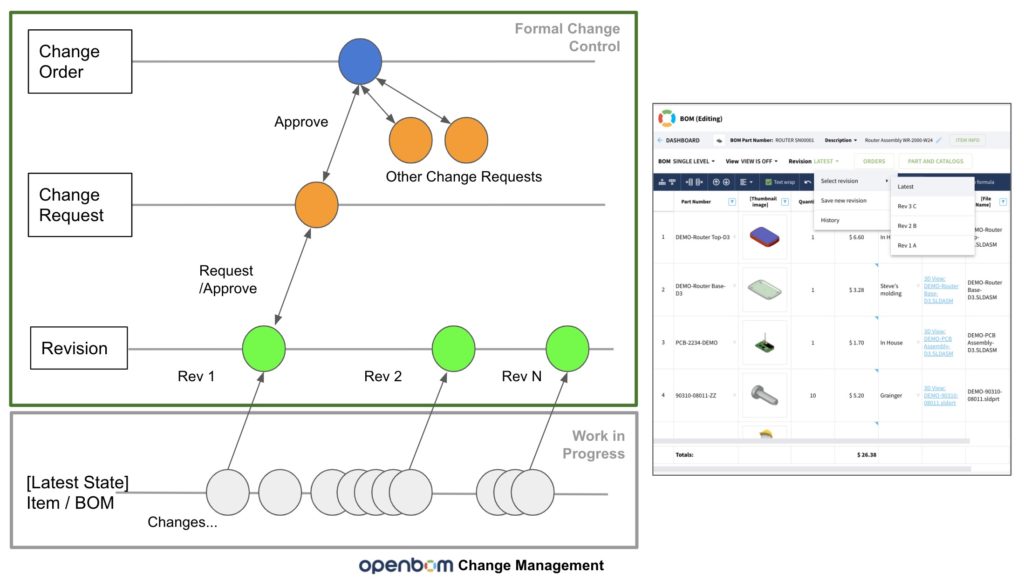

My third example is from OpenBOM (disclosure – I’m CEO and co-founder). All work you do by changing data for items and Bill of Materials is done in the so-called “Latest State”, which is the idea as the trunk (in GitHub) or Workspace (in Onshape). This is a place where all work can be done and it always represents the best so far representation of BOM or items. At the moment of time, the design is coming to a specific maturity level, as a user, you can initiate the creation of a new revision. To put it in the formal configuration control process you can use Charge Request and Change Orders to support the process of approvals and reviews. The following picture gives you an idea of how it can be organized.

Why do we need real-time collaboration in PLM industry

An online collaboration and PLM revision control is becoming very important for the industry. The demand for product lifecycle management software is growing, which is caused by companies looking at how to manage product data and an entire product lifecycle. PLM system vendors’ challenge is to provide the system that can stand the needs of the business systems to provide a response to companies owners and operation managers to connect product development and business operations.

The complexity of product data management is growing as a result of different macro and micro-processes. Product complexity is growing, the demand for digital product data that is capable to support en entire lifecycle including business partners, supplier collaboration for a modern environment, but also capable to handle existing workflows in the companies. Complex products lead to the complexity of cross-functional quality processes, quality management, product cost management, compliance management, and many others. The best PLM software will be able to introduce a novel modern PLM environment and also will fit the strategy of digital transformation and connecting PLM systems to other business processes.

New collaborative systems are the way for many manufacturing companies to transform their activity and get prepared for a digital future with new SaaS products.

5 Benefits of Collaboration in Rev Control

The new collaborative methods and systems bring not only new functions but provide a substantial number of benefits by providing a new connected product development environment. It is fundamentally different from the old systems mostly focused on files and documents. Here is my take on the top 5 benefits of bringing real-time collaboration in the change management process:

(1) Always get access to updated information (never work on the snapshots)

(2) Increase the speed of changes processes. It is critical to move faster in this world

(3) Simplify communication. Old change management and rev control make it so complex.

(4) A better granularity in traceability and change history

(5) Instant data sharing and streamlining user experience for the team.

What is my conclusion?

Novel technologies are coming to support change management and revision control. These systems will impact the traditional space currently occupied by document management systems (eg. PDM/PLM), partially enterprise resource planning, and some manufacturing process planning. Revision control is super important for all these processes and systems used in other disciplines such as portfolio management, compliance management, project management, and others. The fundamental difference is in the way these technologies support collaboration and data modification that can be done together by a number of users. You saw examples of GitHub, Onshape, and OpenBOM above. But there are others too. The main improvement of these processes is to keep ongoing collaboration and data editing continuously between revisions. This is what is done in trunk (GitHub), workspace (Onshape), and collaborative “latest state” (OpenBOM). Users can collaborate and access data simultaneously for changes. At any moment of time, the user can capture immutable Revision that will serve as a baseline for the change and will be preserved independently and will become traceability for a formal control. The modern combination of real-time collaboration and formal revision control and change management process is what makes these systems stand out. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital network-based platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

The post How Online Collaboration Tools Will Change PLM Revision Control appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.