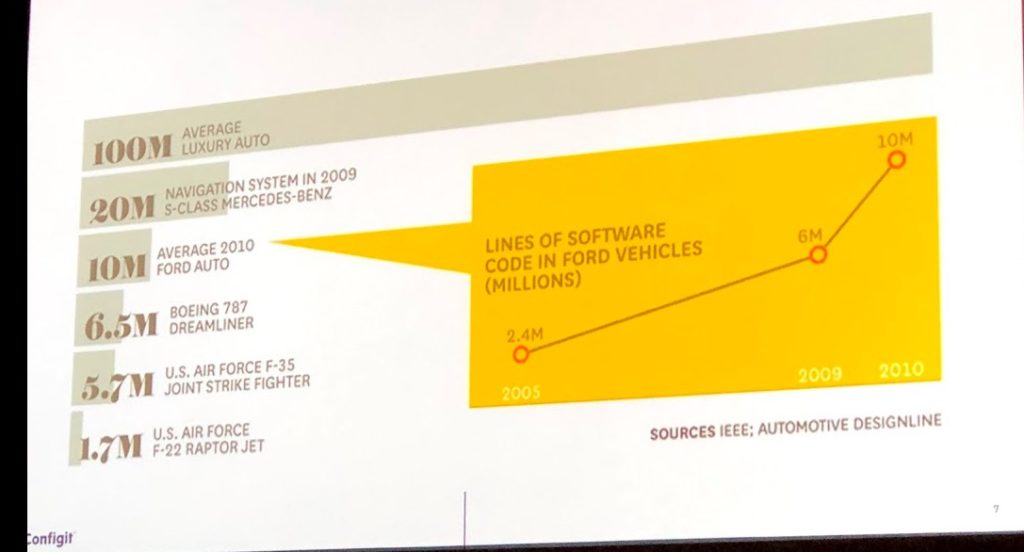

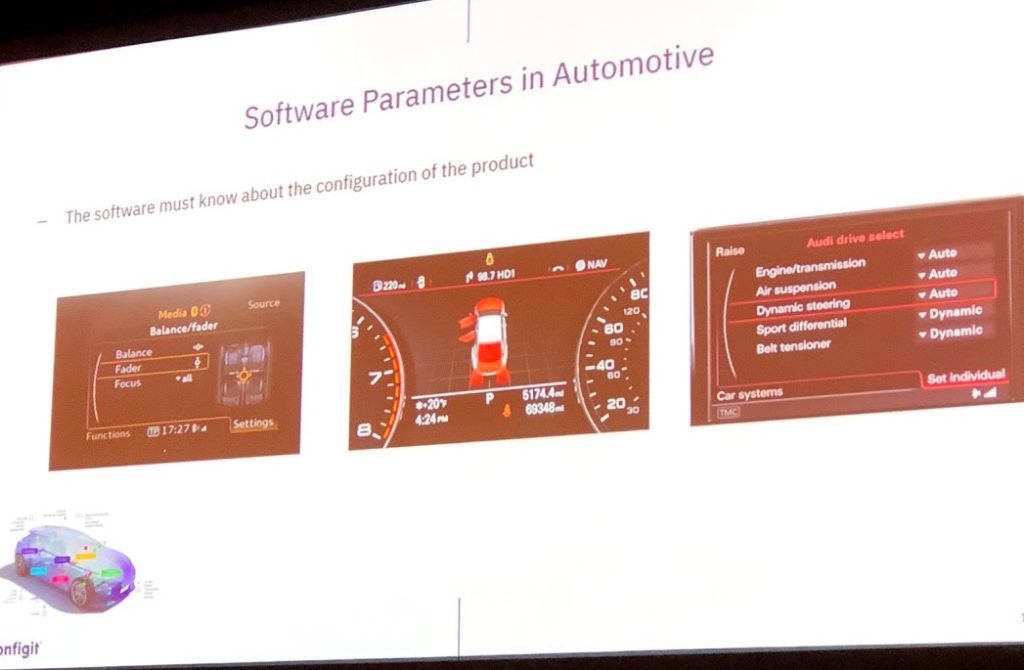

The importance of software in modern manufacturing product is hard to underestimate. For the last decade we’ve seen how complex mechanical products are transforming into sophisticated electro-mechanical products and later growing up to a platform to run software code. Think about automobile and the number of mechanical units replaced by software code.

I captured the following slide earlier this week at ConX18 conference. You probably seen these numbers before, but anyway… this is a mirror any manufacturing company is facing today.

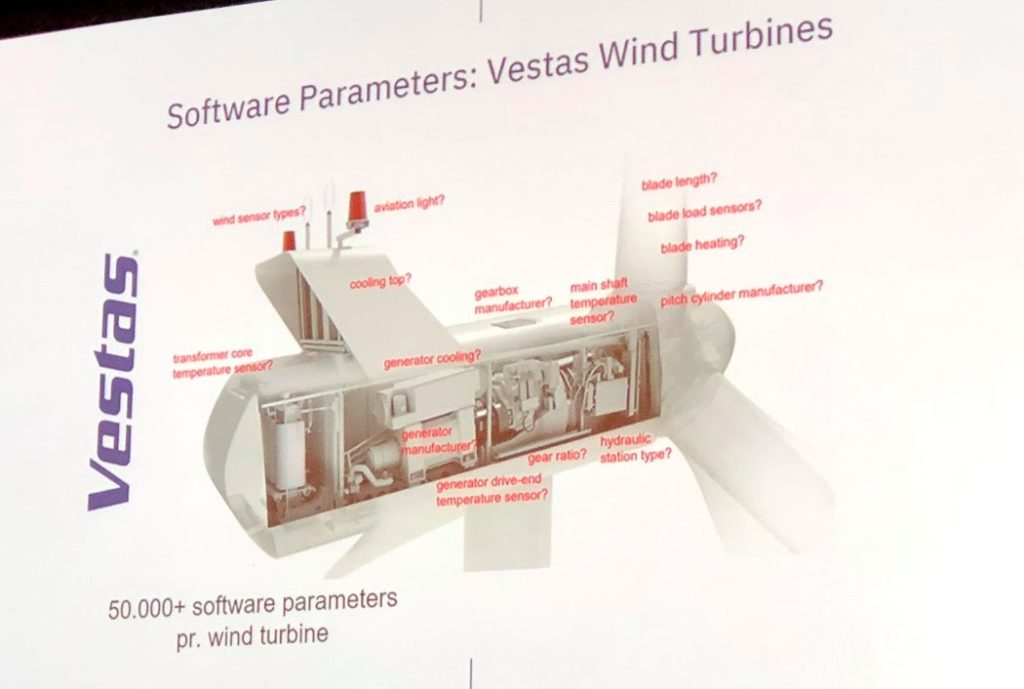

The example of car and turbine that needs to be configured with 1000s of parameters is not a joke. This is a reality of modern manufacturing.

The importance of software created a high level of awareness in the industry about the need to manage software code together with product development. You probably seen some of my articles about it. Few links – What process can connect PLM and ALM tools and How to combine engineering and software BOMs.

Industry awareness and growing complexity of product development created set of urgency and fueled PLM / ALM acquisitions. The most notable is probably Siemens PLM + Polarion. It created lot of discussions about how to perform PLM + ALM integrations. Check one of them – Why PLM and ALM traceability is hard.

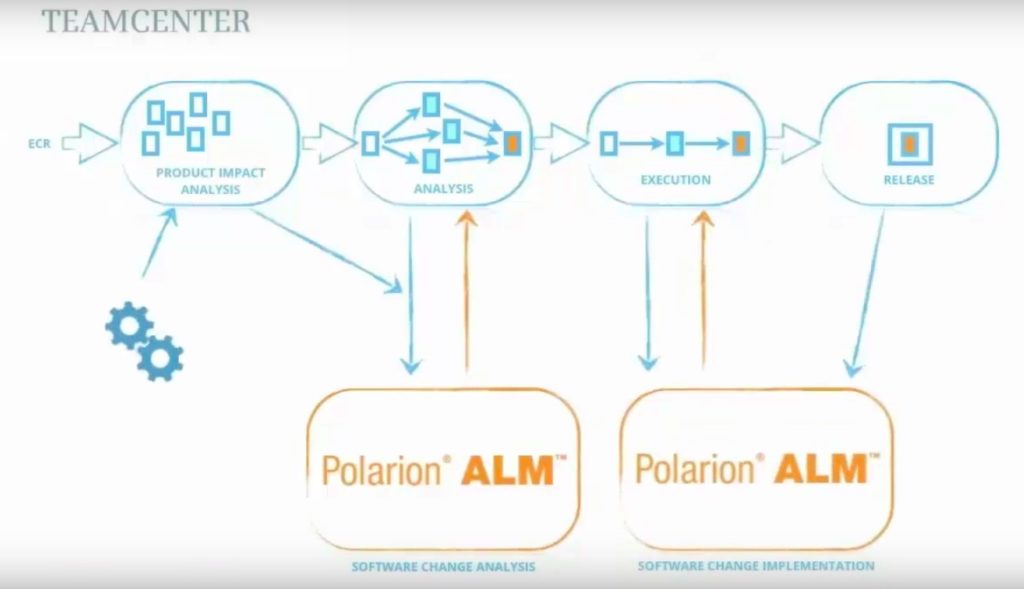

There are many presentations about PLM-ALM integration. Most of them are focusing on how both ALM and PLM products are exchanging information and engaging into change management processes. Here is one example (but you can find many)

Discussion about PLM – ALM integration made me think about what importance of product model concept. The definition might be sometimes different. You might hear about manufacturing / engineering BOM and software BOM. Recently system engineering became a focal point to manage conversation about managing both mechanical and software aspects of the product as as single system. Integration model is a key to build a synergy between PLM and ALM.

Here is a question I want to raise and to ask you to share your opinion. Do you see ALM and PLM will continue as independent systems? How much different produce model in ALM and PLM tools (besides different names and products today). Is there an opportunity to simplify this process and create a unified model for PLM and ALM? While integration is incredible important, potential unifying of models can create an opportunity to simplify the process.

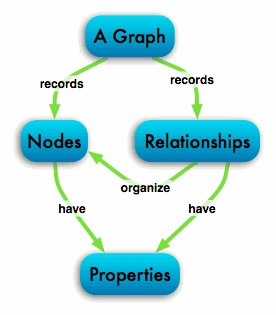

Recently, I’ve been talking about PLM adopting graph model as way to make solutions simpler and more powerful. Check here for more. I think, the same graph model can serve the process of unification between PLM and ALM tools.

What is my conclusion? Both PLM and ALM made its own way to the current development level. As much as each of these systems is independent, it will be naive to think that integration is a natural way to management product models. Car, airplane or even simple thermostat has a single model that contains mechanical parts, electronic components and software modules. To unify them together can bring many benefits – create a simple change management processes, improve data traceability and more.. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing cloud based bill of materials and inventory management tool for manufacturing companies, hardware startups and supply chain. My opinion can be unintentionally biased

The post Can we unify PLM and ALM models? appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.