Better, faster cheaper. This simple formula defines everything we demand from manufacturing until now. In the past century, the realization of such demand came from the ideas of mass production. To build a production line, tune it once, switch it once and keep continues manufacturing going. Later, the challenge to move from mass manufacturing to mass customization changed the formula of success. Building of adaptable mass customization pipelines required end to end integration between engineering and manufacturing. Read some of my articles about mass customization here.

In my view, PLM systems didn’t play significant role in the process of mass customization. However, Mass customization was a real reason why PLM systems wanted to manage MBOM. For most of the companies I’ve seen, MBOM integration realization came via complex PLM-ERP integration pumping data between two systems and adjusting pieces of data here and there.

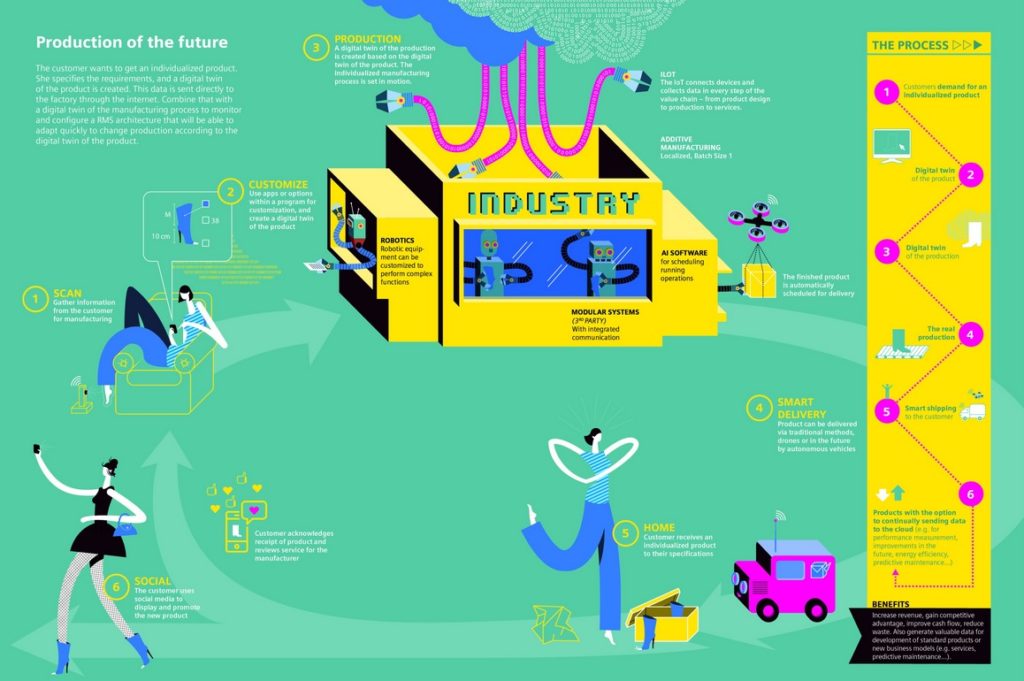

Here is a new trend. Not only better, faster, cheaper. In many cases, “better” now means – make it for me. The demand for individual production is another challenge manufacturing companies have to deal with. Siemens PLM blog published an article The factory of the future where topic of individual production is playing a central place in of future production and IT systems involved into the process.

The challenge of individual production is to with individual customer to connect to the factory. It sounds very futuristic and so I found a key passage about how to organize such factory and projects.

Producing individual products is easier with smaller products at this point. With a simple product like a shoe, or a shirt, you measure the person digitally and then make it. These are relatively simple procedures, because only one product is done on one or two machines.

What happens if you need six or seven operations like assembly, machining, and welding? You have to schedule it optimally so that all the machines will be busy all the time, and each part needs a different processing time on each machine. It is very difficult to build the software that will schedule the orders. Which product will go first?

For mass production you solve such operational problems once, and that’s it. With individualized mass manufacturing, every day brings a slightly different product and you need a new solution. You are not producing this product by itself. You are producing it simultaneously with another four or five products. What Siemens does in this context is important – among other things, they provide the interface between all the parts of the factory, between customers and suppliers, the supply chain, and the machines – everything is talking the same language. This reduces the time from order to delivery.

You can appreciate a very nice picture made Siemens PLM.

As every futuristic picture, it shows relationships and methods that not exist. It made me think about how such ideas can be implemented using existing software and tools. In most of cases, building a completely new systems isn’t an option for manufacturing companies. It is all about layering new systems on top of existing processes and tools. So, what if I will need to implement it using existing software systems and tools. What will be the impact? How production flow will be organized? Most importantly how information flow will be organized? The last one is not less important than production. Because information flow is a key in connection pieces of individual production together.

You can see a process – scanning a person or capturing custom requirements, creating production mode, smart delivery, maintenance and customer services. Everything must be organized and connected. And this is where I see some challenges. Here are 3 significant system challenges I can see:

1- Single tenants and data silos. Organized pockets of data created mechanism to control information and insure changes aren’t happening without approvals. But, extensions beyond existing silos are hard and mostly using “package exporting”. You can be shocked by finding zip files and Excels as a most advanced technologies to make it happen.

2- Absence of out of the box integrations with existing online services. Delivery services, e-commerce, customer relationships, marketing, sales. There are lot of services online that need to be involved into individual production. And integrations aren’t there….

3- Absence of mature REST API. Although it was discussed a lot for the last 5-7 years, most of established PLM systems are just tapping int Web APIs and REST service. It is still a long way until these systems will provide a reliable connecting technologies.

What is my conclusion? Individual production is a very nice vision. I can see huge potential there for future optimization in manufacturing and building a new production system tailored to growing demand of customers to build based on their specific personal needs. It might not be applied in all industries, but it will be coming. Existing PLM systems aren’t ready for this step, in my view. It is a perfect time for PLM strategists and engineering IT managers to come up with requirements and gap analysis. Just my thoughts…

Best, Oleg

Want to learn more about PLM? Check out my new PLM Book website.

Disclaimer: I’m co-founder and CEO of OpenBOM developing cloud based bill of materials and inventory management tool for manufacturing companies, hardware startups and supply chain. My opinion can be unintentionally biased.

The post Individual production and PLM platform challenges appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.