It is not a big secret that PLM vendors are stuck to provide a good solution for mid-size manufacturing companies. The list of failures is too long and I will not mention it in this blog post. It includes attempts to scale down high-end products, build solution atop of office and content management infrastructure, use cloud-based technologies to differentiate and many others. It just doesn’t work. Feature comparison, nice UI, affordable price, out-of-the-box solution, industry templates… mid-size business is a special nut to crack.

PLM market today is great for large companies. There are few very large providers of solutions for very large manufacturing firms in automotive, aerospace, defense, heavy machinery and industrial equipment manufacturing. These solutions are pushed down to mid-size companies with no much success. There are few companies looking how to scale existing PLM paradigm down by innovating in technology or focused industry verticals. But they are invisible in terms of market share.

Mid-size manufacturing companies are ending up with simple PDM vaulting, cloud-based file sharing, Excel-ware and custom development. After few years of following PLM for SMB, I thought PLM vendors gave up on mid-market and focused on new initiatives such as IoT, cloud, big data, machine learning, etc. But, I can see some changes are coming.

Tech-clarity e-book Finding PLM to Fit Mid-Sized High-Tech Companies explains how smaller companies in the high technology industry find themselves stuck between full-featured Product Lifecycle Management (PLM) systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. E-book is sponsored by Dassault Systemes. Read the summary or give one of your emails to DS and get the e-book.

The following passage explains what happened to mid-size companies.

Midsize companies may find themselves in-between because: (1) Product and organizational complexity drive them beyond basic PDM capabilities; (2) A full-featured PLM implementation may feel out of reachMidsize manufacturers need to choose a system that quickly delivers the core capabilities they need to streamline product development but also gives them room to grow value over time. So what’s the right size PLM to fit a midsized high-tech company?

Read the article and draw your own conclusion. The recommendation provided by Jim Brown e-book is to focus on so called “Core PLM”.

Core PLM can quickly add value to midsized high-tech companies by helping them combat complexity, improve productivity, and innovate faster to meet market needs. Recognize the potential value of a fully featured PLM with all of the bells and whistles, but be honest with yourself about how much time and effort your company can afford to get there (at least right away). Don’t take on too much. Start with the basics and get value quickly, but recognize the shortcomings of simple file sharing solutions that fall short for the complex, multi-discipline products and product development environments common to midsize high-tech companies. Look for a solution that allows you to design in the context of your products in real time, but also in the context of processes and product development projects. In addition, look for PLM that incorporates automation including automatic project updates to keep engineers focused on innovation instead of managing files.

Core PLM is a very nice marketing buzzword. It gives you a feeling of something solid and reliable. Core PLM sounds like something you can probably trust and rely on. Besides, it is not clear what does it mean… E-book gives very little explanations what is actually “Core PLM”. My best hunch is that “core” means – manage design projects, stay close to supply chain and customers and manage products and programs holistically. But it doesn’t give a recipe how to make it happen.

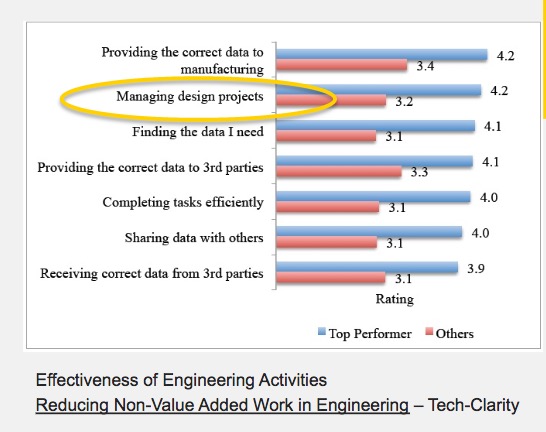

The only picture giving you some ideas about functions included into core-PLM:

My biggest surprise was not to find of bill of materials (BOM) as one of the basic elements of data management for manufacturing companies. I need to confess and this is not a secret for my readers that I’m CEO and co-founder of openBoM. So, I understand my opinion is biased. Even so… c’mon, show me high-tech manufacturing company without the need to manage BOM for mechanical and electronic components. If BOM is out, core PLM is a glorified name to use for CAD file management and vaulting. Following my sandwich analogy, if CAD is a bread, then peanut butter and jelly is a BOM :).

I can see a rational behind starting small and expanding PLM solution with additional value. However, I wonder where is a critical solution mass that “core PLM” will deliver as a starting point for mid-size manufacturing company.

What is my conclusion? Core PLM is a new PLM marketing buzzword for mid-size companies. I like it more than out-of-the-box solutions, best practices and industry templates. However, mid-size business is a hard nut to crack. It looks like Dassault Systemes is embarking into a new journey to figure out how to sell to mid-size businesses. As one of the largest PLM vendors, Dassault Systemes can create an industry wave and other PLM vendors will join the trend. Nobody will like to idea to left behind. Interesting time to be in PLM business. Just my thoughts…

Best, Oleg

Want to learn more about PLM? Check out my new PLM Book website.

Disclaimer: I’m co-founder and CEO of openBoM developing cloud based bill of materials and inventory management tool for manufacturing companies, hardware startups and supply chain. My opinion can be unintentionally biased.

The post Core PLM sandwich for mid-size manufacturing companies appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.