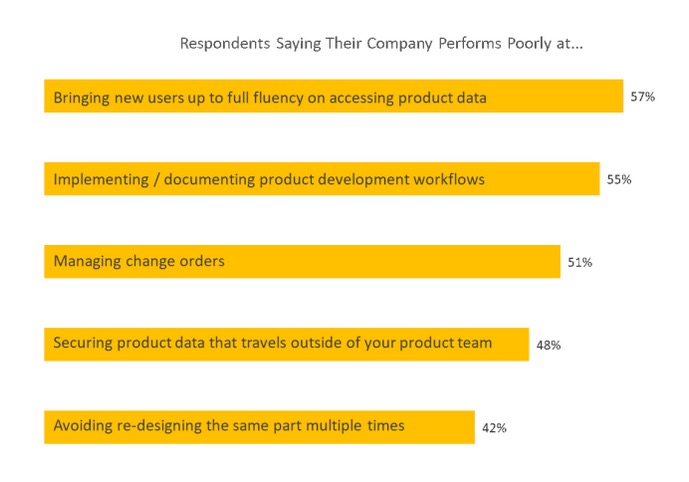

Five Ways Product Design Teams Fail at Data Management article by Engineering.com brings results of survey Engineering.com did to learn about design data management. The survey was sponsored by Solidworks. You can learn why product design teams fail at data management. The following chart gives you an idea about what is wrong with product development processes – data is poorly accessed, workflows are complex to manage, it is hard to share data outside of engineering.

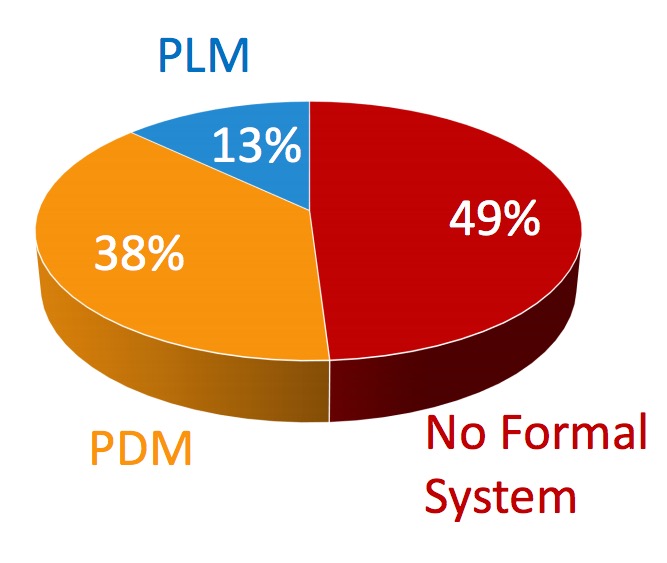

The following link gives you an access to the full report (you will have to give up one of your email addresses to Engineering.com, which I did already long time ago). Inside I found some interesting data points. The first one is related to the percentage of CAD users not using any PDM system:

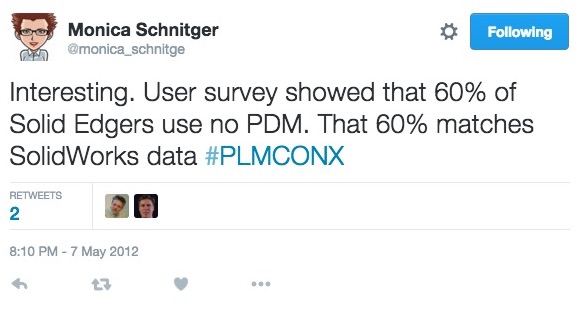

Although the number is still pretty high (49% of users doesn’t have any formal PDM system), I found it is significant improvement over the situation 5-10 years ago when majority of CAD systems were unmanaged. As you can see the number referenced by Monica Schnitger in 2012 that number of users with no PDM is about 60%. So, I can see an improvement here for the last 10 years.

The survey made me think about many problems product development organizations have and possible solutions to resolve. Although, the research is heavily focused on CAD file management, I think, the problem is not PDM. These days PDM can be acquired from CAD vendors or from one of PDM providers (some of them are free). The problem is how product development, engineering and manufacturing organization is organizing their data an processing to make it efficient. The following conclusion in Engineering.com survey is a good confirmation for that:

The most commonly reported important features to look for in a data management system were: (1) Easy to access from within your primary CAD system; (2) Allows easy, secure external data sharing; (3) Adaptable to our workflows without external customization.

What is my conclusion? I think vendors did maximum they can to bring reliable and affordable PDM system to manage CAD files. As user, you have variety of options (including free ones) and still 49% of customers are not using PDM systems. I can see 2 main reasons for that – 1/ CAD file management doesn’t solve the problem and the problem is wider; 2/ Regardless how efficient you manage files, the paradigm is bad and leads to inefficiency. So, organizations should take a broader look on how to manage product data – requirements, design, bill of materials, manufacturing plans and contract work to improve what is wrong with product development processes. Just my thoughts…

Best, Oleg

Want to learn more about PLM? Check out my new PLM Book website.

Disclaimer: I’m co-founder and CEO of openBoM developing cloud based bill of materials and inventory management tool for manufacturing companies, hardware startups and supply chain. My opinion can be unintentionally biased.

The post Engineering.com PDM survey – clear results and not obvious conclusion appeared first on Beyond PLM (Product Lifecycle Management) Blog.

1 Comment on this article