For the last few weeks I had a chance to speak to many people in engineering and manufacturing with no PLM twisted mindshare. They are very good people, believe me. They are working in design, engineering and manufacturing. They are building real stuff. They do CAD, Bill of Materials, machining, 3D printing, electronics. They just didn’t get into PLM…

For them and many others that stumbled on my blog, I wanted to write a simple 5 paragraph explanation about how PLM work. Sounds like a good deal for Thanksgiving Holidays? I hope so.

1. Data management application

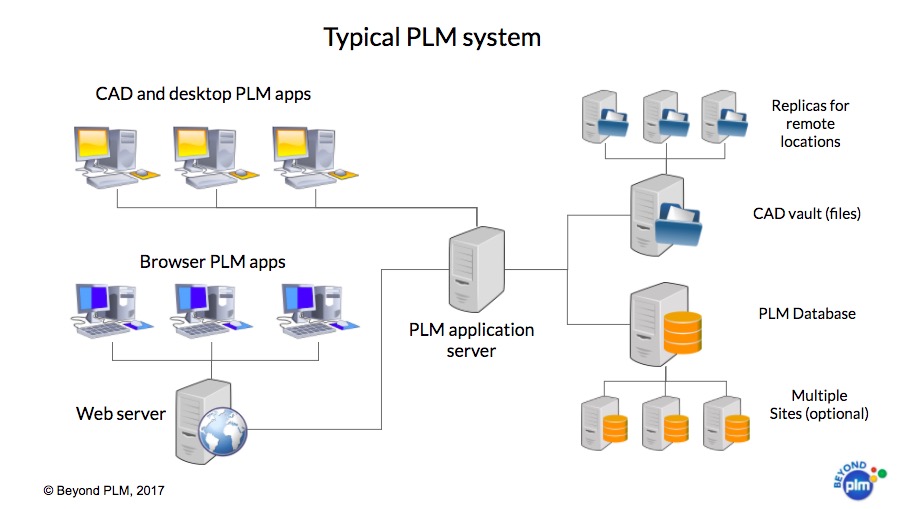

From information architecture standpoint, PLM is just data management application. It has all standard elements of data management – database, application servers, web servers and clients. The heart and key element of PLM – data model and tools to support data management. Most of PLM these days are flexible data management tools capable to tailor it to specific customer requirements. Clients can be browser based on installed rich application. The trend for the last decade was to make them web / browser based, but you can find lot of legacy stuff still available in running as Windows 95 apps.

2. CAD files

Combining all together, PLM system can be explained as a system composed of database, vault for files, server(s) and client applications.

Design and engineering is a space where PLM was born. Therefore very often PLM is associated with CAD systems. I think, majority of manufacturing companies are using desktop CAD systems, so to talk about CAD files is important when you talk about PLM.

One of the function of PLM system (often called PDM) is allowing you to do CAD file management by storing information about CAD files (meta-data) in databases and files in a secure location (vault). You might see similar file management functionality in other application, but specifics of PLM/PDM function is to manage complexity of CAD file relationships (typically CAD project is stored in multiple files).

3. Combining files and data management

PLM data management creates an information environment where users can define multiple “objects” representing products and related components. The information is usually highly configurable. It is hard to predict what data engineers and other people want to store and manage. Also, it is usually hard for engineers to agree about something. 2 engineers – 3 names for the same thing (joke).

Data is usually presented in a way of hierarchies and data grids. Files are usually presented in image previews with complex visualization functions allowing to rotate, zoom, slice and dice 3D model or 2D drawing.

The information “soup” supported by PLM system is not simple. Product structures, relationships, bill of materials… you name it. This is a main reason why PLM systems is much more complex than your average data management applications.

4. Tasks and everything else…

Most commonly used function of all PLM application is to manage tasks. In most of the PLM systems, “process” is the name that used to represent a task that can be shared and routed between multiple people. You can think about it as simple sequence of operations.Workflow is a technology used to move tasks between people. What makes it complex is dependencies on other pieces of information and files.

5. Single organization, multiple organizations

The days when manufacturing company is located in a single building are over. Therefore, to support work in multiple locations and multiple organizations is an important function of every PLM system. To do so, PLM systems are using variety of data management techniques helping to access data everywhere. But usually PLM database (also known as a single version of truth) is created for each organization. If you partner with somebody you need to export / import data or to allow to people from other organization to login to your PLM system.

6. A big picture…

What is my conclusion? As you can see, basic PLM is not a rocket science. It is possible that PLM companies, PLM consultants and PLM pundits will disagree. Making things complex is easy. Charging people for complexity you created can be a good business until somebody will figure out how to disrupt the complexity. Many complex businesses were disrupted by internet and new technologies. PLM is a good disruption target. It is complex and reluctant to change. Just my thoughts…

Best, Oleg

Want to learn more about PLM? Check out my new PLM Book website.

Disclaimer: I’m co-founder and CEO of OpenBOM developing cloud based bill of materials and inventory management tool for manufacturing companies, hardware startups and supply chain. My opinion can be unintentionally biased.

The post How PLM works: a primer for engineers to top managers (or anyone, really) appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.