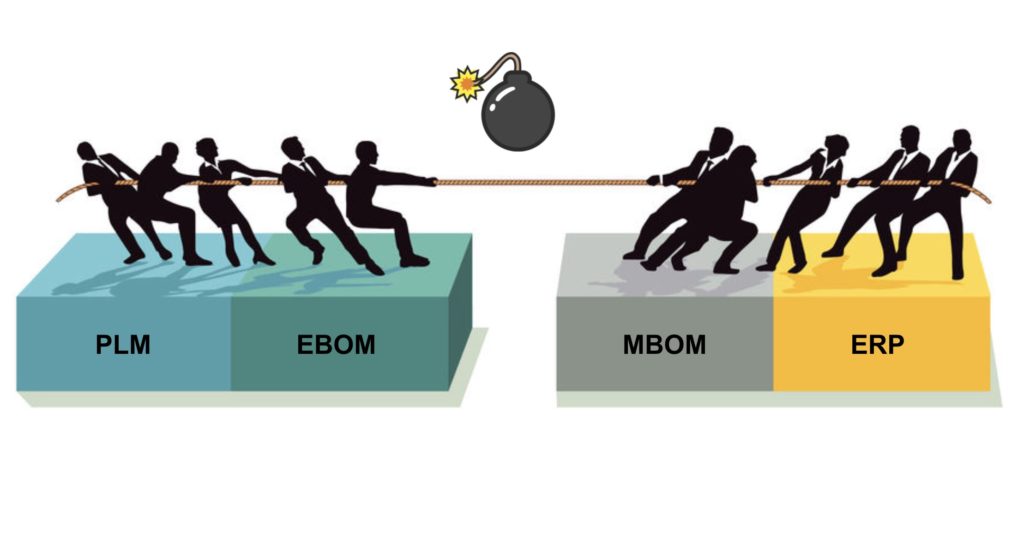

PLM and ERP are the two most dominant enterprise systems when it comes to handling product information and product development process, yet the number of debates about their coexistence in manufacturing companies is endless. What is PLM for and why ERP only is not enough is one of the most popular. Both PLM and ERP vendors promote capabilities to manage BOMs, changes, files, and related information about the products and how they can divide and conquer. PLM vs ERP debates about BOM ownership is another very often discussed topic. What is the right option for your company – two BOMs (EBOM+MBOM) or Single BOM? Who should own MBOM and many other topics?

In my article today, I want to touch on some of these topics, but most importantly to raise the question and discuss if SaaS PLM can change the trajectory of PLM and ERP development as well as the current status quo of PLM and ERP vendors.

PLM vs ERP Vendors Standoff

Most of the large ERP vendors stepped into some sort of PLM business (via acquiring PLM companies) or OEM PLM solutions. The challenge of ERP companies is to penetrate the early appearance of PLM vendors in manufacturing companies to capture the data and strategic position within company IT. You can see examples – SAP PLM, Oracle – Agile PLM, Infor – Aras. All these companies have one (or sometimes even a larger number of PLM systems). We can also see some opposite opportunistic movement of PLM vendors acquiring ERP systems (Eg. DS acquired IQMS). The huge number of smaller ERP systems are focusing on specific industry verticals, market niches, and companies of smaller sizes. You can see their attempts to provide some PLM functions.

While PLM vendors sometimes still feel not appreciated enough (compared to ERP), I can see the evidence of early adoption of CAD / PLM / BOM Management solutions in new manufacturing companies and it happens much earlier than companies are embarking on ERP system adoption. CAD/PLM vendors are a better fit today for early-stage manufacturing companies. Contract manufacturing is another contributor to this status quo because these manufacturing companies can use CMs without running their ERPs and they can use PLM/BOM management solutions to communicate with CMs/. So, ERP vendors are facing the reality of working with engineering data once they are coming to deploy ERP solutions for the first time and one of the popular questions is how to integrate engineering within ERP because a company already has an advanced CAD, PDM, or PLM system. The status quo is not different in large companies. Although, practically all of them have ERP systems in place, these systems largely disconnected from new product development and product development units. The request “to send an Excel to SAP” is one of the most popular, which means these systems are not well integrated into engineering data and live in a silo.

What System Comes First?

This is one of the questions any manufacturing company is asking. Where to start? Is ERP the first business system company should acquire? What about PLM? Is there a need to bring both systems together? I can hear these questions every day. Here are some observations after working with thousands of companies in different industries and companies of different sizes.

- Design (CAD), finance, and inventory are systems that usually come first during the manufacturing companies’ formation stages. Companies usually are afraid of complex ERP systems at this stage, but very much interested in how to capture the data from design and engineers to organize it. Excel is the 2nd best system ever, but there is growing evidence that companies are looking at how to get rid of these Excel files.

- From a certain company size and product complexity, most manufacturing companies are running ERP or advanced inventory planning systems. This is also the time when every company starts to experience the problem related to engineering to manufacturing data handover.

- There is a growing number of manufacturing companies recognizing the importance of PLM systems and growing interest in how to get product data (BOMs) and related engineering data under control. After engineering to manufacturing handover, this is the biggest space using Excel data management.

Manufacturing Companies – Demands and Challenges?

Connected systems. The mantra of today is how to connect everything and PLM-ERP relationships are experiencing the same level of challenges. Customers are looking for seamless data handover between business functions. The idea of siloed data repositories is getting more rejections and the demand for “easy integration” is prevalent and highly valuable. But to get systems connected is easy say than to get it done. The amount of old ERP systems is gigantic and companies are facing a number of challenges in understanding how to organize the process.

For larger companies, there is a big question of data ownership between PLM and ERP and multiple vs single BOM question is one of the most complexes. PLM vendors can offer a better EBOM to MBOM translation, but these solutions are extremely complex and out of reach for many companies from both cost and complexity perspectives. Most ERP systems don’t have a good grip on EBOM and connection with the CAD environment, which puts ERP systems at disadvantages and helps PLM vendors to take a strategic position in product innovation and most importantly in data access.

Can SaaS Change PLM and ERP Development Trajectory?

SaaS technologies are bringing a big change in the enterprise world in the way how systems are delivered and integrated. These systems are usually simpler and more open. SaaS allows seamless integrations via REST API and also able to perform a much easier data handover. Will it be a good opportunity to change PLM-ERP relationships and to simplify processes?

I think, there is an opportunity here. The name of the game – seamlessly connected services. The opportunity for ERP companies (especially SaaS ERP vendors) to establish engineering connections and protect their business status. On the other side, the development of SaaS PLM and CAD systems made data exposure much easier. While there is a very small number of PLM companies in this space, SaaS technology coming from both sides (PLM and ERP) can help to solve generation-long problems.

What is my conclusion?

Both ERP and PLM vendors will try to reach into the “neighborhood” to support their position within the customers. Seamless PLM (engineering) to ERP (procurement, inventory) functions can become a strong differentiator for some vendors and help to acquire manufacturing customers earlier in the process and growing their market share. Larger companies can embrace new SaaS architecture to streamline processes. The adoption of SaaS technologies is skyrocketing and ERP/PLM vendors that coming fast into this space can enjoy fast-growing adoption of their services. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital network-based platform that manages product data and connects manufacturers, construction companies, and their supply chain networks. My opinion can be unintentionally biased.

The post PLM vs ERP Tug Of War appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.