I want to come back to my conversations about the construction industry. If you’re long time readers of my blog you might remember my articles PLM and BIM – common roots or common future; PLM vs BIM – common or different? and Cloud Data Management – A common future for PLM and BIM. Manufacturing and construction industries are moving on collision trajectories. Many construction projects, especially for prefabrication, look very much like manufacturing. Modern buildings are complex high-tech objects with a significant amount of infrastructure created by manufacturing companies.

For the last several months, I’ve been involved in multiple discussions about the construction industry. I came back to AEC via customers that started to use OpenBOM (disclosure – I’m CEO and co-founder) to manage the definition of detailed assets for construction objects such as doors, mechanical and electric equipment, prefabricated houses, and units of larger buildings such as bathrooms and others. It made me think a lot about the intersection of manufacturing and construction technologies again.

Earlier this month, I attended AU2020. The unfortunate online event format, allowed me to attend and cover many tracks. The one I want to mention today is about Autodesk Tandem. If you missed the announcement, check it out here – Autodesk Tandem Brings Digital Twin To Building Information Modeling.

Brings Digital Twin To Building Information Modeling.

From design through construction, the project delivery lifecycle of buildings, facilities, bridges, and other physical structures creates an extraordinary amount of data. The data is often disorganized and left unused after handover to owners and developers when the project is completed. And building owners want digital data at handover given nearly 80 percent of an asset’s lifetime value is realized in operations.

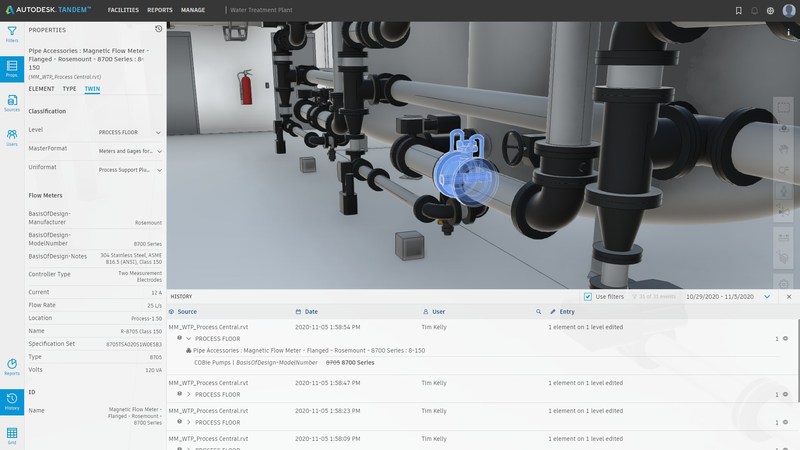

With Autodesk Tandem, all project models are brought into a single platform, creating a digital view of projects, along with metadata for each asset. Architects, engineers and contractors can then fully support the digital handover, giving owners a digital twin of the final asset so that they can dive into all design and construction history. Leveraging nearly 25 years’ leadership in intelligent 3D design and engineering, Autodesk credits Building Information Modeling [BIM] as one of the foundational components of Autodesk Tandem.

There is a lot of information online about Autodesk Tandem. I found a comprehensive set of links and resources on Kean Walmsley’s Through the interface blog – Autodesk Tandem and the Forge Viewer Data Visualization Extension.

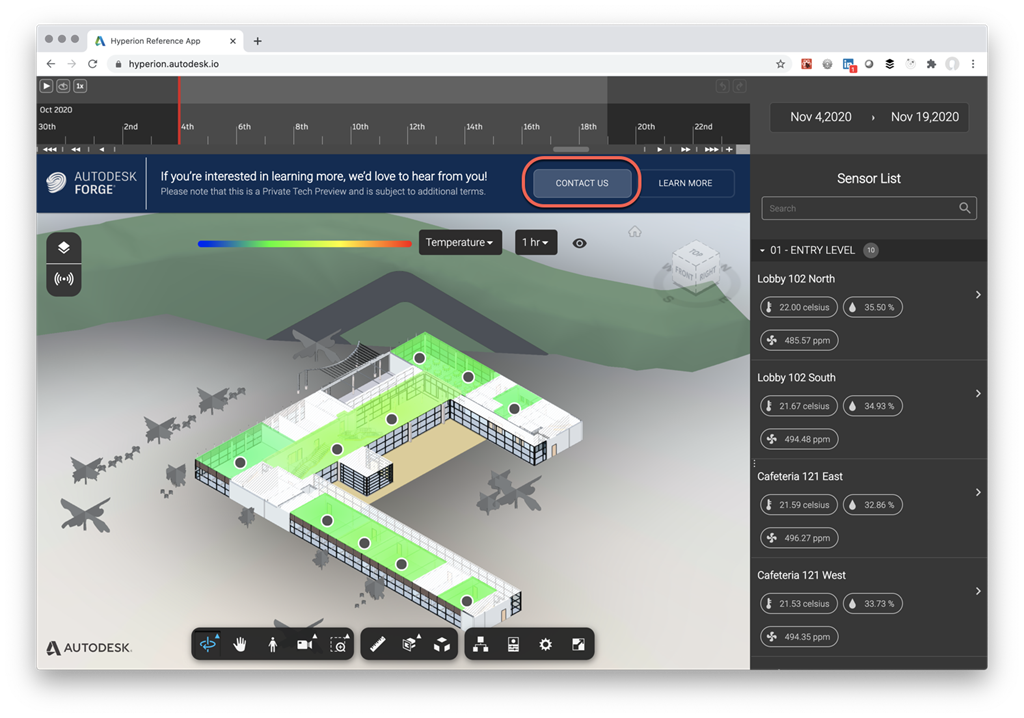

During the AU 2020 General Session and the AEC Keynote we heard about Autodesk Tandem, a new product and platform for creating Digital Twins from BIM. During the Forge Keynote, we heard about the Forge viewer’s new Data Visualization Extension, which simplifies the mapping of (for instance) sensor data into the viewer. I was following Project Dasher for few years and Forge Visualization is very interesting too.

For more information, I recommend you to check Ken’s AU class –Lessons from Project Dasher: Building a Digital Twin Using Forge.

Autodesk Research has been exploring the intersection of BIM (Building Information Modeling) and the Internet of Things (IoT) for the last decade. Project Dasher integrates sensor data with model data from Autodesk’s Forge platform to contextualize IoT data in 3D. This session will look at what is happening with Dasher, but also will talk in detail about the Forge capabilities that Dasher has used—which are available to all Forge developers—to build a digital twin integrating real-world performance data.

Digital Twin – A common grounds for manufacturing and AEC

Digital Twin is a popular topic for many manufacturing companies these days. You can find Digital Twin mentioning in the agendas of all PLM vendors. Together with Digital Thread, it is one of the most promising ways to move PLM technology forward. However, if you look at both AEC/BIM objects and manufacturing objects, you can find many common technologies, tools, and approaches. Even though the terminology might be different between manufacturing and construction, the commonalities are very visible – comprehensive data modeling for digital assets, visualization, and collaboration. The building lifecycle and product lifecycle can have more in common when we move to the future of digital technologies.

Autodesk Forge, ACC and Autodesk Fusion 360

For Autodesk products, Forge is a common ground between manufacturing and construction. Forge is used by design and manufacturing technologies and products such as Fusion360 and also is part of new ACC (Autodesk Construction Cloud) products. It will be interesting to watch how the number of Forge components used by Manufacturing and AEC projects and products will increase.

What is my conclusion?

Construction is rightfully called the weakest manufacturing industry. With the introduction of modern manufacturing industries and new modern methods of data management, digital modeling, and visualization, Digital Twin can become an interesting step to use existing and new manufacturing, PLM and data management technologies in AEC projects. Will it become a step into consolidating technological efforts for PLM and BIM? Are we going to see more PLM and related technologies in construction projects? Those are interesting questions to answer in the next few years. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital network platform that manages product data and connects manufacturers and their supply chain networks. My opinion can be unintentionally biased.

The post Can Autodesk Digital Twin Tandem Consolidate PLM and BIM Efforts? appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.