Autodesk University is one of my favorite events for many years. This year it is different. Usually, the event attended by around 10,000 people, it was converted into a fully digital event attended by 100,000 people virtually according to Autodesk. Over the course of last months, I attended many virtual events, so I have some comparison points. Some of the events look no different than a web meeting with real people. Some companies go in a full virtual live event and some go in the recording. Autodesk provided a mixed experience. With a digitized augmented background, it was not always obvious if people were presenting from a real Autodesk facility or a person was sitting in the middle of his living room.

What I can say almost for sure is that Andrew Anagnost, Autodesk CEO was filmed at Autodesk Pier 9 in San-Francisco.

The event called Reimaginee Possible is available online here, so there is almost no point to share screenshots and visuals. Everything is available live and if you’re interested you can go online and watch the sessions and presentations. I think you can easily spend next month watching. I attended general sessions, keynotes, and Q&A with management. Also, I attended and plan to attend sessions related to products and announcements done by Autodesk.

Connected and Collaboration using Data

Data, Connection, Collaboration. These three words came in many presentations. For the last few years, Autodesk provided a message about the importance of data and how Autodesk puts data in the center of everything. With so many products, covering many disciplines, the data is a real challenge and opportunity for Autodesk. You probably remember my Data Comes First from AU2018 and Intelligent decisions from AU2019.

This year Autodesk speaks about how to use data and automation to reimagine the way we build things. It doesn’t matter what things – construction objects, manufacturing products, or media. The data and connections will help to coordinate, collaborate, and converge different disciplines. The workflows between teams and companies need to be supported. Data should be flowing from one place to another between different stakeholders. It applies to both construction and manufacturing. Actually sometimes, it is hard to differentiate and see the borders because the borders between construction sites activity, prefabrication, and manufacturing activities are blurring.

Data and AI

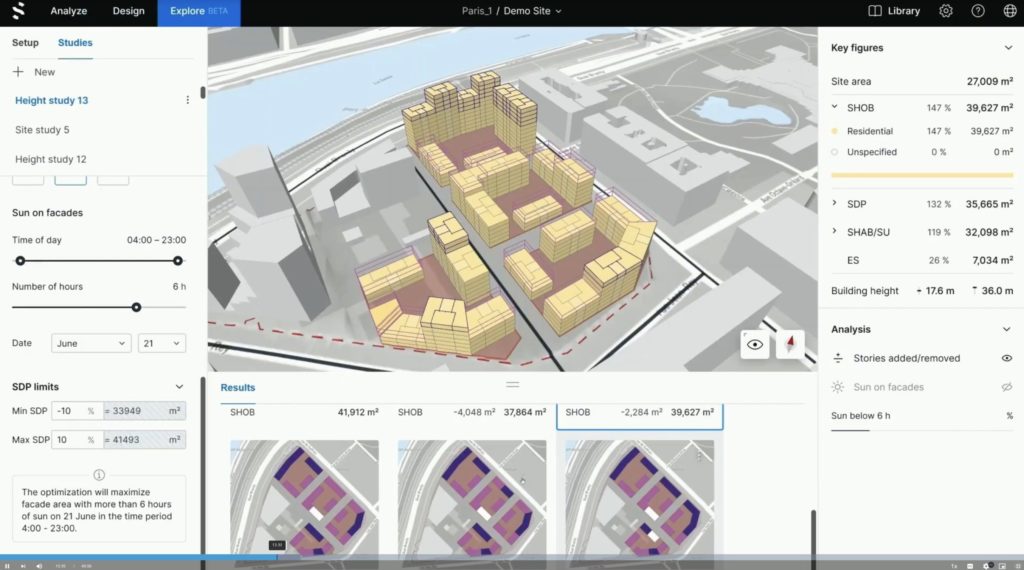

The major announcement for Autodesk during the event was the acquisition of Spacemaker – a company using data, AI, and machine learning for urban development and planning.

Autodesk is planning to integrate Spacemaker into ACC (Autodesk Construction Cloud). Also, Autodesk has longer plans to use Spacemaker AI technologies in other products including Revit.

Spacemaker is a confirmation of Autodesk’s long-term strategy on how to bring data into the process to drive intelligent decisions. I expect this technology to get combined with other Autodesk services for intelligent decision-making.

Data Sharing and Collaboration

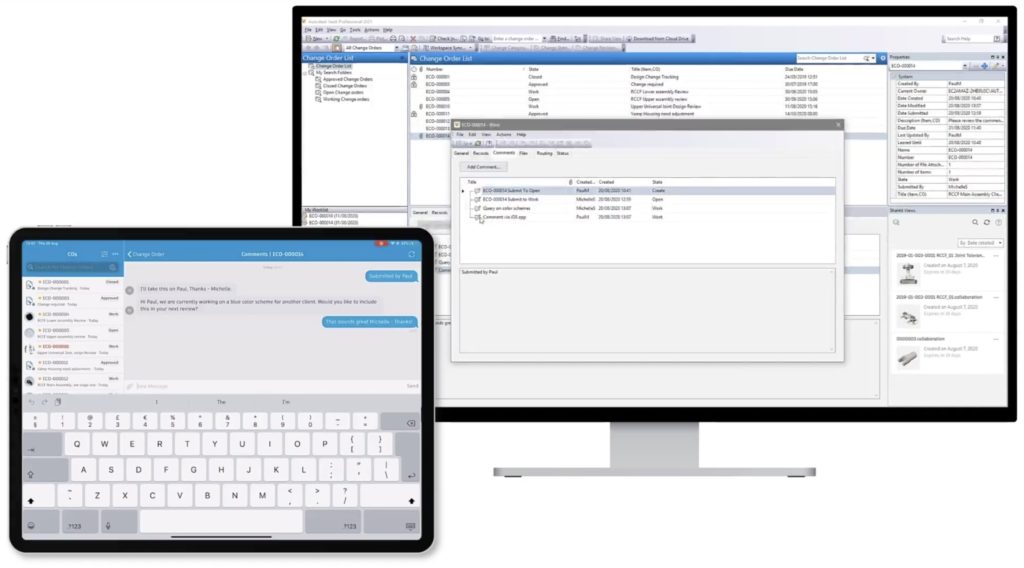

The message about data sharing is coming from everywhere at Autodesk. A new product Autodesk Build and Autodesk Docs is a new generation of cloud products, part of Autodesk Construction Cloud and planned to replace existing BIM360 Docs. I need to dig more here. As it sounds, Autodesk is rebuilding some existing construction products to use acquisitions from the last year.

In manufacturing, the same message comes across from multiple presenters from Autodesk, speaking about how data can be shared and how collaboration processes can be supported. Multiple services are involved in this process. It is also an Autodesk Forge platform as an enabler of data collaboration and data sharing.

But it is also coming from existing products that are getting new extensions, such as Vault mobile.

Design to Manufacturing Process

My favorite topic is to explore how data will help to connect design and manufacturing. According to Autodesk Srinath Jonnalagadda and Derrek Cooper, data is a way to bring silos. Autodesk is planning to support multiple ways to break silos. It starts from Autodesk’s common data experience, the ability to access data everywhere, convergence from 2D to 3D, moving from a desktop environment to a cloud environment, and providing a unified data experience.

Fusion 360

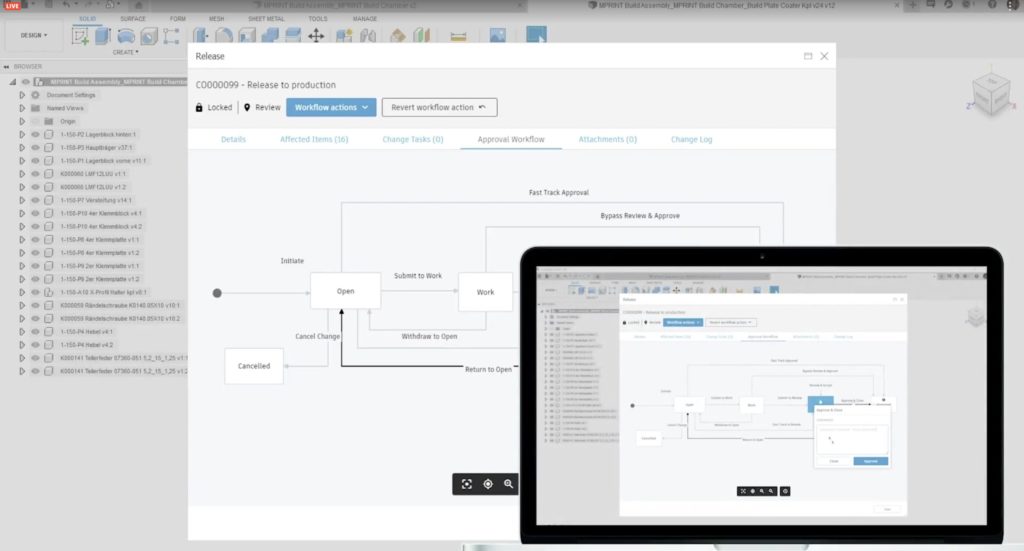

Autodesk continues to build Fusion360 as a common design and manufacturing environment connecting processes and applications. The new announcement this year is Fusion 360 Extensions. One of them is bringing an advanced Release lifecycle process to Fusion360 users.

Fusion360’s customer base is growing. The data point I captured during the presentation is 650K active Fusion360 users and 100K commercial customers. It means Fusion360 is on a very interesting trajectory to grow in the manufacturing industry.

According to Stephen Hooper, VP and GM of Autodesk Fusion360, the future investments of Autodesk in manufacturing will be focusing on any areas where automation, converging processes, and using digital platforms will allow to get rid of non-value tasks.

The challenge is how to connect the pipelines in processes from concept to the production, connecting people remotely and other places.

Autodesk FORGE platform

A decade long continuous investment of Autodesk into Forge platforms is bringing many benefits to products and services. According to Susanna Holt, VP of Forge, Autodesk is expanding APIs and cloud data services, and expanding the role Forge plays in many existing and new applications at Autodesk. Forge is a foundation for the Fusion360 platform and the new Autodesk Docs (part of the Construction cloud). Here is an interesting data point about the usage of the Autodesk Forge Platform.

Live Q&A with Construction, Design & Manufacturing, and Forge

My favorite session was live Q&A. Well organized and orchestrated, with great insight from Autodesk Management. It would be much better to have it live and I’m missing the live AU. But this is the best we can get this year. Thank you, all!

What is my conclusion?

Data, connection, intelligence. With the super large set of applications and data sources supported by Autodesk in all domains and products, placing data in the center is the only possible strategy. It is encouraging to see how Autodesk is continuously building data platforms and pipelines for diverse data workflows to connect people and processes together. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing a digital network platform that manages product data and connects manufacturers and their supply chain networks.

The post How Data Can Bring Value? My notes AU 2020 appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.