Last week I shared my thoughts about What platform is needed for Digital Thread? Thanks for your comments and discussion online and offline. The topic seems to be trending and the amount of publications about Digital Thread is growing.

At the first glance, you can think about that digital thread is something new. Digging more, you can find that ideas of connecting silos and companies by sharing common data are not new and were around with different initiatives, technologies, and names before. I can hear ideas about the next opportunity in the development of middleware technology and data federation. On the functional side, you probably remember all discussions about as-designed, as-build, as-operate, and as-maintained data representation.

As I outlined in my previous article How to build Digital Thread… Slow, the digital thread is a shared and connected information space. Every person and organization plays a specific role in the process of building and using the digital thread. It connects OEM companies, contractors, suppliers, engineers, customers, and actual products together. It must be created to provide value, otherwise, it is dead and won’t survive. People and companies are collectively playing a role in building digital thread network platforms and the digital thread is a living system. I like to think about Facebook as a great analogy of digital thread in the real world – real social data thread.

So, Digital Thread is connecting companies together. My attention was caught by Aircraft IT article How I See IT: Digital threads and twins in MRO by Allan Bachan, VP, Managing Director, MRO Operations, ICF. The article brings some interesting data points about the digital thread and digital maturity of manufacturing organizations in aerospace industry.

A full digital thread from ideation through to the first flight and delivery of the B777 aircraft continues to be one of pride for Boeing. The B777 is also frequently dubbed the ‘most successful aircraft in aviation’. Throughout the protype production, and for all subsequent aircraft, digital twins with digital threads – up to Boeing’s handover to operators – have existed.

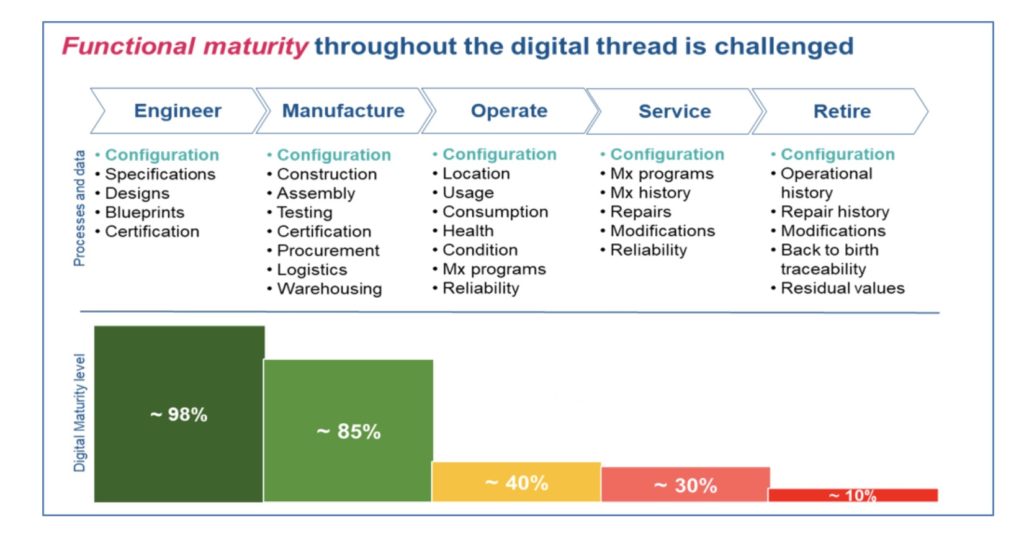

One observation in the realm of civil aviation is that the ideate, design and manufacture processes are more digitally mature than the operate, maintain and retire processes. In fact, there is a noticeable drop in the digital thread maturity between the Manufacture and the Operate functions in the cycle and another between the Operate and the Maintain functions as shown below.

The picture above gives a good presentation of companies involved in Digital Thread. The picture also is a good demonstration of the importance of the connection between companies organizing digital threads. While digital maturity in various industries can be different, the concept of digital thread connection organizations involved in product development, manufacturing, maintenance, and support will be the same.

This picture helped me to think future alongside the lines of what PLM architecture is needed to support such digital environment. Here is my take about 3 dimensions of PLM architecture development we will see in the near future to support Digital Thread.

1- Multi-tenant data management

There is very little chance all companies involved in Digital Thread will accept the usage of the PLM platform controlled by a single company (eg. OEM). Therefore, PLM architectures will be evolving towards the development of better multi-tenancy support. Multi-tenancy today only available for PLM SaaS platforms and I expect these technologies to grow and expand in larger organizations.

2- Improved real-time cross-platform Integrations

There is very little chance that companies involved in the building of Digital Thread will accept a single vendor platform from one of the big PLM vendors. Which means we are going to see multiple platforms and demand for integration between them. Old integration practices are still around, but I bet on new web architectures to build integrations including REST API services, event-driven, and microservice architecture.

3- High Availability (HA) software architecture

High availability (HA) is a characteristic of a system that can ensure an agreed level of operational performance, usually uptime, for a long period of time. The idea of HA is not new and used by many web infrastructures. However, in the PLM world, most of the established systems were developed before HA architecture became widely adopted. I can see how PLM systems are lagging behind in the delivery of HA solutions and architectures. But, Digital Thread is not possible with HA PLM architecture.

What is my conclusion?

Digital Thread spans across multiple organizations and therefore demands different PLM architecture. A traditional PLM architecture is a single database that stores all information belonging to a single company. All variations of traditional architectures such as federation, enterprise integration, data representation, and views are not changing the fundamentals – a single database at its core. At the same time, the nature of Digital Thread is a set of connected information assets. If all you need is to connect data in a single organization, traditional PLM database architecture can do some work. Anything beyond that will require rethinking PLM architectures. Just my thoughts…

Best, Oleg

Disclaimer: I’m co-founder and CEO of OpenBOM developing cloud based bill of materials and inventory management tool for manufacturing companies, hardware startups, and supply chain. My opinion can be unintentionally biased.

The post How to Rethink Traditional PLM Architectures For Future Digital Thread appeared first on Beyond PLM (Product Lifecycle Management) Blog.

Be the first to post a comment.